Tailor-made process

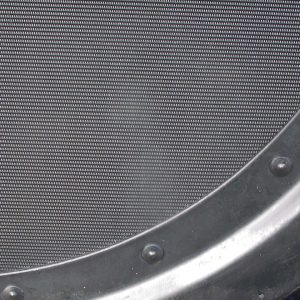

The chemical cleaning of coolers, filters and heat exchangers requires experience and space.

Cleaning these installations is a specialty in which Vecom has become skilled during the past decade. In addition to determining the material, the alloy of the metal surface, the contamination must also be precisely determined for the correct treatment. This is done with the help of the in-house laboratory. On the basis of the results, the correct cleaning liquid can then be composed for, as an example, a circulation process. This is necessary for the repair of corrosion resistance after new construction or the removal of process contamination.

Large baths and lifting capacity

With a total bath volume of approximately 300 m3 and a lifting capacity of 20 tonnes, Vecom can handle any challenge. And otherwise we will just come to you.

The cleaning process is always made fitting for the installation

Vecom has various cleaning processes for cleaning coolers, filters and heat exchangers. Determining the suitable process depends on the one hand on the material and the contamination and on the other hand on the use of the installation. The cleaning of the installations is done in one or more steps with alkaline, neutral or acidic chemical cleaning agents.

A solution for every problem

With the above techniques, Vecom can clean practically all coolers, filters and heat exchangers for every possible application and, if desired, provide treated material with cleaning certificates.