Environmentally friendly and effective alternative

Every company with transport pressure piping in its production system is familiar with the problem of internal contamination and fouling in those pipes. This can lead to various problems, ranging from loss of efficiency to blockages and corrosion. A known cleaning method is chemical-technical cleaning with which the pipes are cleaned with chemicals.

In some cases, however, the cleaning method by means of pigging offers an environmentally friendly and effective alternative.

Advantages of pigging

- Less chemical waste compared to chemical cleaning (more than 90%);

- Faster and more effective filling of pipes without air bubbles;

- Faster and more effective hydrotesting;

- Making gas and pipe walls explosion-free faster and more effective.

The process

Pigging uses a flexible cleaning plug, the so-called "pig", which is pressed through the pipe with the help of a certain medium. The diameter of the pig is just slightly larger than the inside diameter of the pipe.

The pigs are always brought into the piping system to be cleaned from a "pig station" or launcher. The launcher contains at least one connection to the medium with which the pig is pushed forward. As a rule of thumb, this is a gas such as nitrogen or air, but it can also be a liquid such as water.

At the end of the pipeline, the pig and the medium are collected in a so-called "receiver", the second pig station. In the "receiver" the pig is separated from the medium. If the medium is water or product, this is separated with an additional connection. These pig stations can also be part of the fixed system or as mobile installations.

The three applications for pigging

There are various reasons for applying the pig method:

- Cleaning a pipe

- Emptying a pipe

- Inspection of pipes

Depending on the contamination, the material type of the pipe or the production purpose, the pigs have different sizes and are coated with a coating and/or are finished with a wire brush made of steel, stainless steel or Teflon.

1. Cleaning a pipe

Cleaning of pipes by means of pigs can be done in different ways, depending on the contamination to be removed and the reason for the cleaning. To remove loose dirt and the like from a pipe, mechanical cleaning with 'brush' pigs is generally sufficient. Pigs are shot until the pigs look visually clean. Afterwards, a pipe is usually checked for cleanliness with a boroscope. Mechanical pig cleaning always takes place by propulsion with air or nitrogen. In order to be able to propel a pig, the volume of air or nitrogen is especially important.

Chemical cleaning with the help of pigs is often performed to save chemicals, thereby reducing the release of hazardous waste and evidently preserving the environment.

The process of chemical cleaning with pigs generally consists of several steps: degreasing, pickling and passivating, the so-called "cleaning train".

Construction of the "cleaning train" for stainless steel pipes

- Degreasing with a light alkaline cleaning agent;

- Pickling with a strong acid based on nitric acid and hydrofluoric acid;

- Passivation with a nitric acid-containing passivation agent.

The pigs are used as a separation in this process, so that it is possible to alternate between the cleaning agent and demineralised water. Between the cleaning steps, a precisely matched amount of rinsing water will be used to rinse the metal surface of cleaning agents. At the end of the pipeline, the various chemicals are separated from each other and collected for waste processing.

Why a reduction of chemical waste by more than 90%

Thanks to this working method, the use of chemicals is handled sparingly (compared to circulation) and significant time savings can be made. For example, a 500-meter long DN250 pipeline has a capacity of 25 m³. A chemical cleaning of this pipe, consisting of different phases and rinsing steps, would result in a waste volume of more than 125 m³. A chemical "cleaning train" using pigs, limits the total amount of waste to 10 m³. In short, a reduction of more than 90%.

Mechanical cleaning with pigs always takes place by propulsion with air or nitrogen. The volume of air or nitrogen is important to be able to propel a cleaning pig. Of course, tailor-made solutions are also possible for each specific project.

2. Emptying a pipe

Fixed transport pipes to tanks often contain standard fixed pig stations to completely empty the pipes during a product change, and possibly to clean them, before moving to another product load. This method prevents contamination of products in fixed transport lines.

3. Inspection of pipes

In places where inspection of pipes is not easy (for example, under the ground or under the sea surface), so-called "intelligent pigs" can be used. These type of pigs contain all kinds of measuring equipment enabling the pipe to be examined for wall thickness, corrosion, location, etc.

Vecom provides tailor-made solutions

Due to the flexibility of the pig, angle bends, T-pieces and other deformations are no problem. The diameter of the pipe system is also not an obstacle to working with pigs. By using a system that builds from soft to hard and pigs with different coatings increasing in diameter, almost all pipes can be safely, quickly and perfectly cleaned. The quality of Pigging has proven itself in/at:

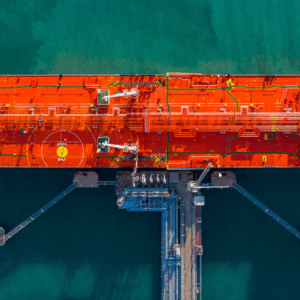

- The chemical and petrochemical industry

- The food industry

- Drinking water companies

- Sewer pressure pipe management

- Offshore industry