Prevent contamination of the process or medium in the installation or system

Stainless steel systems and installations are periodically cleaned before commissioning and in many cases to remove process contamination such as scale.

Metal surface treatment

Stainless steel must be chemically cleaned before use. The corrosion resistance of stainless steel is determined by a chromium-rich oxide skin. Once this oxide skin is formed, there is a passive surface.

Corrosion

Stainless steel is not completely resistant to corrosion. It is important that light corrosion is removed to prevent, among other things, pit corrosion with all associated negative consequences and to prevent contamination of the process or medium in the installation or system.

Why pickling and passivating

During the installation of the stainless steel pipes in a system and / or installation, the surface is exposed to many mechanical and thermal treatments. This causes damage to and contamination of the protective oxide skin. This results in the loss of corrosion-resistant properties. The base material will therefore corrode faster. It is therefore very important that the chromium-rich oxide skin is intact and clean before the system or installation is put into use.

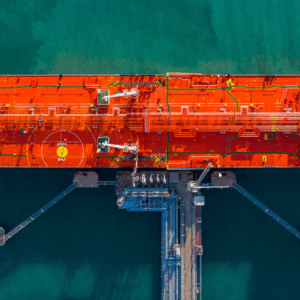

Pre-commissioning cleaning

Pre-commissioning cleaning of austenitic stainless steel generally involves three steps: degreasing, pickling and passivating. Degreasing is necessary to remove oil, grease and atmospheric contamination and to make the surface optimally accessible for the pickling agent. The pickling treatment removes iron particles and other contaminants from previous treatments on the material such as welding, handling, etc. After pickling, the material is rinsed with low-chloride water to remove acid residues. The pickling treatment results in a chrome-rich surface.

Although the stainless steel will spontaneously passivate after pickling (forming a protective chromium oxide film) by exposure to sufficient oxygen in the outside air, closed systems are generally chemically passivated. The passivation fluid is circulated through the installation or system using acid-resistant pump units. The duration of this treatment depends on the type of stainless steel and the temperature. Analysis of the iron content and acid concentrations determine when the treatment is complete. The treatment is followed by rinsing, first with drinking water and then with demineralised water.