Specialist in metal surface treatment

The Vecom group has been a leading metal surface specialist in Europe for 70 years. We are specialist in the conditioning of stainless steel. We provide our services within our own metal laundries (located in The Netherlands, Belgium and the UK) and we can provide our services on-site (worldwide).

Metal surface treatment services

Advantages of metal surface treatment by Vecom

- Flexibility

- Responsibility

- Large crane capacity

- Highest quality, risk free

Flexibility

Vecom knows the challenges of her customers. Vecom is a service company and does everything she can to optimally serve her customers. Feel free to contact us, even when a special situation has arisen, or when there is a shortage in time.

Responsibility

Vecom ensures that the waste water streams (also on-site) are collected and processed. 100% Responsibility is taken for the chemicals used. We are also constantly working on more sustainable cleaning agents in our in-house laboratory.

flexible cooperation, where

treated materials are delivered

on time, every time."

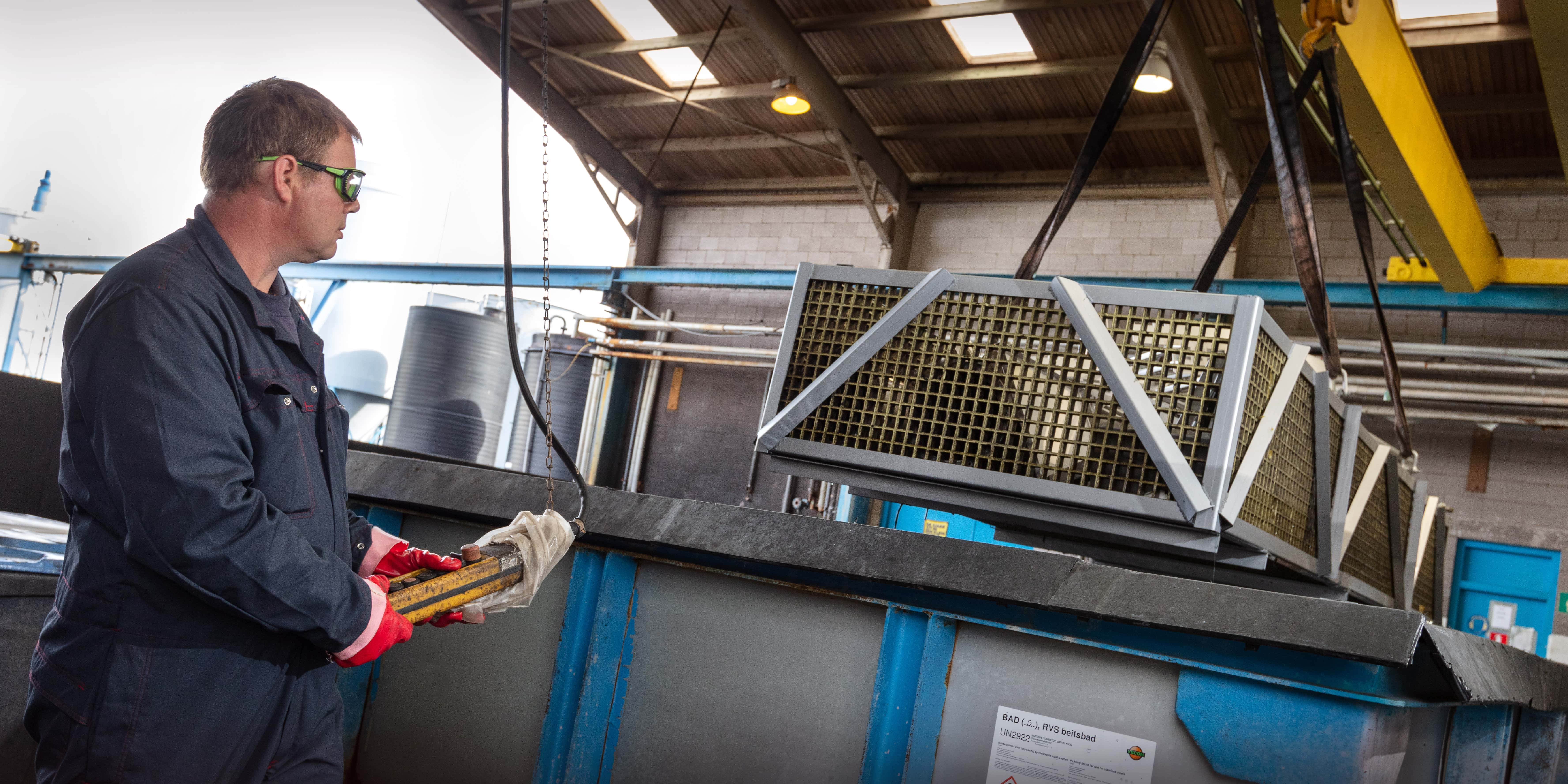

Vecom's lifting capacity

With the substantial lifting capacity, the large pickling baths and the on-site possibilities, Vecom ensures that all products can be treated.

Vecom has two locations for pickling and passivating in the Netherlands: Vecom Maassluis and Vecom Enschede. Metals can be delivered and treated at the relevant location.

Vecom can also arrange the transport of the materials. Both small parts and very large parts (such as turbines and gas tanks) can be handled at the Vecom locations.

The largest parts go to Maassluis. Vecom Maassluis has various pickling baths, which vary in size. The largest bath has a size of 14 x 3 x 1.4 meters. The overhead crane has a capacity of 20 tons.

If the installation to be treated cannot be dismantled, Vecom Industrial Services (VIS) will pickle and passivate on-site. There is a solution available for every situation, so please contact us for more information.

Overhead cranes with a capacity

of no less than 20 tons

The highest quality, guaranteed

Vecom has as its core value: safe for people, the environment and metal.

Technical offer

Feel free to request an appointment or a technical quote. Depending on the size of the project, we will first make a site visit.